Sintered segmented bridge saw Milling Profiling Wheels deliver aggressive, long-lasting performance for drainer groove grinding—ideal for precision machining of kitchen worktops, fireplace surrounds, and decorative stone surfaces. These wheels combine metal bond durability with smooth cutting action to reduce waste and rework.

Order(MOQ) :

5 pcsProduct Origin :

Fujian,ChinaColor :

RegularShipping Port :

Xiamen PortLead Time :

7-20 days after paymentCustomized support :

Visualization ServiceBrand Name :

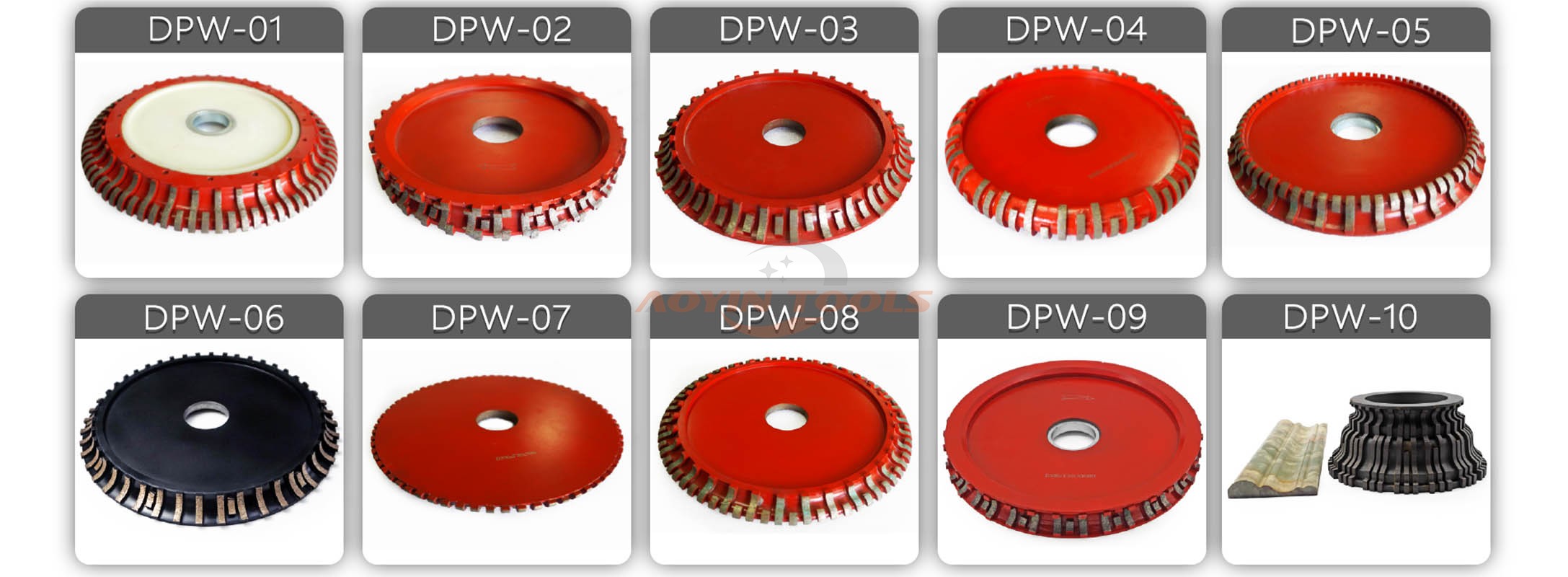

OEMSintered Segmented Bridge Saw Milling Wheel for Drainer Grooves & Stone Decoration

Product Description:

This Segmented Diamond Profiling Wheel for bridge saw are engineered to produce precise semicircular grooves for drainer systems on stone surfaces. Made with a high-quality metal bond matrix, the wheels embed diamond segments that cut aggressively yet cleanly—eliminating chipping and burrs for a finish ready for diamond resin polishing. Perfect for both functional (drainage) and decorative (fluting) applications in stone fabrication.

Product Parameters:

Perfect for:

FAQ - Frequently Asked Questions:

Q1: Can these wheels be used on quartz?

A: Yes—our metal bond formula is adjustable for quartz’s hardness, ensuring efficient cutting without excessive wear.

Q2: How often do I need to replace the wheel?

A: With proper use (correct RPM, feed rate), the wheel lasts 2–3 times longer than standard fluting wheels—typically 50–70 hours of machining.

Q3: Do I need a special bridge saw for these wheels?

A: No—they fit most bridge saws with a 22.2mm bore. We also offer adapters for older models.

Q4: Will the grooves be ready for polishing?

A: Absolutely—the smooth cut eliminates chipping, so you can directly use diamond resin polishing wheels for a high-gloss finish.

Q5: Can I get custom sizes?

A: Yes—we offer diameter thickness and grit customization for specific project needs.