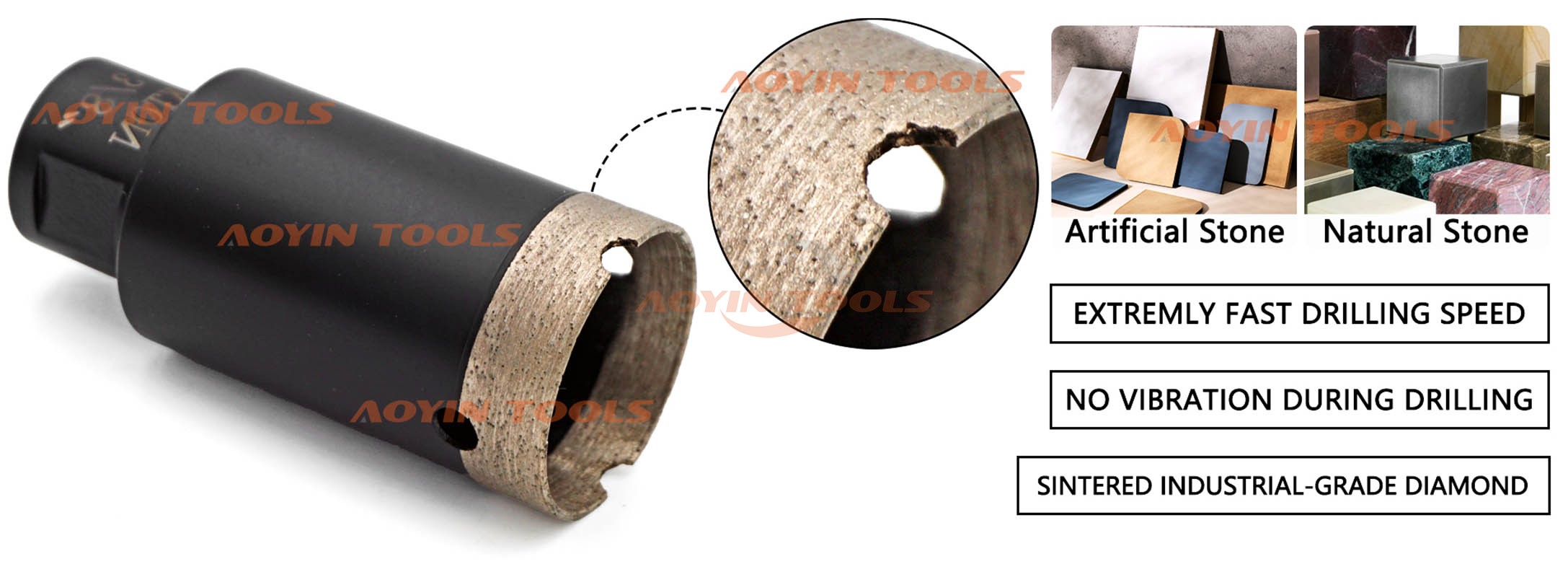

Our Crown Type Wet Diamond Core Bit is engineered exclusively for high-hardness materials like Dekton, porcelain, and UHPC—featuring a thin 2mm rim for fast, clean drilling and water-cooling to prevent overheating. Ideal for CNC machines and professionals demanding precision on ultra-compact stone panels.

Item No :

DDB-01Order(MOQ) :

10Product Origin :

Fujian,ChinaColor :

CustomShipping Port :

Xiamen PortLead Time :

7-20 days after paymentBrand Name :

OEMCustomized support :

Visualization ServiceCrown Type Wet Diamond Core Bit for Dekton Porcelain CNC

Product Description:

This crown-type wet core bit is designed specifically for large porcelain panels and ultra-compact sintered stones including Dekton, Lapitec, Neolith, and Laminam. Its 2mm ultra-thin rim enables rapid, chip-free cuts, while the built-in water-cooling system maintains stable temperatures during long CNC runs—delivering precision, durability, and efficiency for stone fabricators and CNC operators.

Product Parameters:

Product Highlights:

Application Areas:

Perfect for fabricators and installers working with high-end stone materials:

Company Service Advantage:

As a trusted provider of cutting solutions, we prioritize customer satisfaction and excellent service. Our team of experts is dedicated to providing personalized assistance and guidance to help you find the right tools for your specific drilling needs. We offer efficient and reliable shipping services to ensure timely delivery of your orders. Additionally, we provide comprehensive after-sales support, addressing any inquiries or concerns you may have, ensuring your satisfaction with our products.

FAQ - Frequently Asked Questions:

Q1: Can I use this bit on regular porcelain tiles?

A: It’s optimized for ultra-compact stones (Dekton, Lapitec)—not recommended for standard porcelain tiles (which are softer and may cause the thin rim to wear unevenly).

Q2: Why does the 2mm rim matter?

A: Thin rims reduce friction and heat, resulting in faster drilling and flawless, chip-free edges—essential for high-end installations where aesthetics matter.

Q3: How important is the water cooling?

A: Critical for UHPC/Dekton: without it, heat from friction can crack the material or warp the bit. Water keeps everything cool and extends tool life.

Q4: Will it work with my CNC machine?

A: Yes—this bit is CNC-engineered to fit most mainstream CNC centers and deliver consistent, accurate results.

Q5: What’s the typical drilling speed?

A: For a 10mm-thick Dekton slab, expect 1–2 minutes per hole (vs. 2–3 minutes with traditional thick-rim bits)—boosting your productivity by 30–50%.