All-in-one Stone Tool Kit, from Stone cutting to final finish tools which used in stone fabricators. The high quality tools makes your work easier.

4 Inch Diamond Resin Filled Cup Grinding Wheel Product Overview: The 4 Inch Diamond Resin Filled Cup Wheel delivers professional-grade performance with 16 high-strength metal segments for chip-free grinding on granite, marble, and quartz surfaces. Featuring a 5/8-11 female arbor and wet/dry compatibility, this wheel ensures durability and precision for natural stone fabrication shops. Designed to minimize vibration and chipping, it’s ideal for achieving clean seams and removing saw marks efficiently. Key Features 16 High-Performance Metal Segments Reinforced steel segments reduce bouncing and vibration, ensuring smooth grinding on hard stones like quartz and granite. Segmented design prevents segment loss during extended use, maintaining tool integrity. Resin-Filled Diamond Matrix Heat-resistant resin bonds diamond particles securely, reducing wear and improving heat dissipation. Optimized diamond distribution ensures uniform cutting action and minimizes wheel wear. Dual Compatibility (Wet/Dry Use) Suitable for both wet grinding (to reduce dust) and dry grinding (for quick cleanup). Universal Arbor Compatibility 5/8-11 thread fits most angle grinders and polishing machines. Broad Material Versatility Works on granite, marble, quartz, engineered stone, and even concrete edges Core Advantages: Extended Wheel Life: Resin matrix and metal segments reduce wear, lasting up to 300+ square feet per wheel. Chip-Free Grinding: Beveled edge design prevents material digging, ideal for delicate quartzite and marble. Cost Efficiency: Reduces material waste and minimizes wheel replacements, saving up to 30% on grinding costs. Applications: Natural Stone Countertops: Profile edges, bevels, and radius corners on granite and marble slabs. Quartz Surface Fabrication: Remove excess material and refine edges without chipping. Concrete Repair: Smooth rough concrete surfaces and repair damaged edges. Company Service Advantage: We prioritize customer satisfaction and strive to provide excellent service at every stage.Our dedicated team is always ready to assist you with any inquiries, ensuring a seamless shopping experience.We offer prompt delivery, ensuring that your products reach you in a timely manner. FAQ (Frequently Asked Questions): 1. Q: Can I use this grinding wheel with a machine that has an M14 thread? A: Yes, our 4 Inch Diamond Resin Filled Cup Grinding Wheel is suitable for machines with an M14 thread. 2. Q: Is this grinding wheel compatible with machines that have a 5/8-11 thread? A: Absolutely, our grinding wheel is designed to fit machines with either an M14 or 5/8-11 thread. 3. Q: How long does the grinding wheel last? A: The durability of the grinding wheel depends on various factors such as the intensity of use and the hardness of the material being ground. However, our wheel is constructed to provide extended durability and long-lasting performance. Choose our 4 Inch Diamond Resin Filled Cup Grinding Wheel with M14 or 5/8-11 thread options for efficient grinding and precise results. Experience the convenience, durability, and efficiency it offers in your grinding projects.

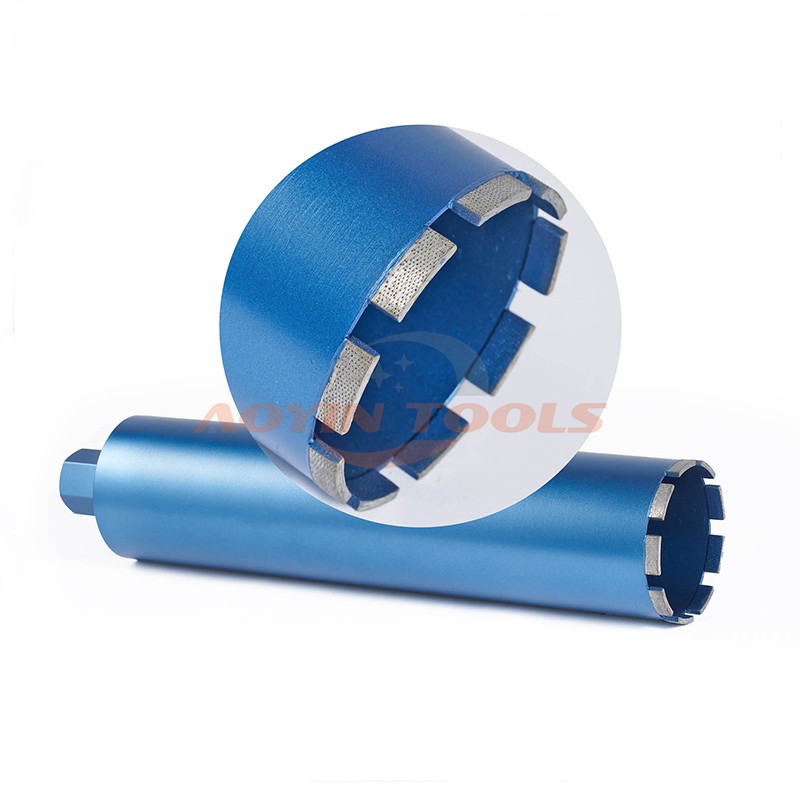

Diamond Segmented Core Bits with Ordered Arrangement for Reinforced Concrete Product Description: The Core Bits are precision-engineered tools tailored for high-performance drilling in reinforced concrete. With a focus on durability and efficiency, these bits are essential for any construction or infrastructure project requiring consistent and reliable drilling capabilities. Product Parameters: Connection Type:1-1/4UNV (Custom threads available upon request ) Power Range:1.5-3.5Kw machines Segment Design : Diamond segments in an ordered array for optimal performance DIAMETER SEGMENT DIMENSION USEFUL LENGTH CONNECTION L T W N 36 16 3.7 12 4 350/400/450/500 (VARIOUS CONNECTION UPON REQUEST) 1-1/4 UNV (VARIOUS CONNECTION UPON REQUEST) 38 16 3.7 12 5 40 16 3.7 12 5 42 24 3.7 12 5 47 24 3.7 12 4 51 24 3.7 12 5 63 24 3.7 12 6 68 24 3.7 12 6 78 24 3.7 12 7 82 24 3.7 12 7 92 24 3.7 12 8 102 24 3.7 12 9 108 24 3.7 12 9 112 24 3.7 12 9 122 24 4.0 12 10 127 24 4.0 12 11 132 24 4.0 12 11 152 24 4.5 12 12 162 24 4.5 12 12 172 24 4.5 12 12 182 24 4.5 12 13 202 24 4.5 12 15 212 24 4.5 12 16 225 24 4.5 12 16 250 24 4.5 12 16 300 24 5.0 12 17 350 24 5.0 12 20 Product Highlights: 1. Versatile Application: Our diamond core drill bits are suitable for drilling all kinds of hardness levels in reinforced concrete, making them versatile tools for construction projects. 2. Enhanced Durability: The laser welding technology ensures superior bonding strength, eliminating the risk of segment fall-off during drilling operations, resulting in long-lasting performance. 3. Exceptional Drilling Speed: These core bits offer an extremely fast drilling speed, allowing you to complete your drilling tasks efficiently and save valuable time. 4. Vibration-Free Operation: The design of our core bits ensures minimal vibration during drilling, providing a smoother drilling experience and reducing operator fatigue. Application Areas: The diamond core drill bits for construction reinforced concrete are widely used in the construction industry for a variety of applications. They are ideal for drilling holes in reinforced concrete structures, such as walls, floors, columns, and beams. These core bits are essential tools for contractors, builders, and construction professionals who require precise and efficient drilling in reinforced concrete materials. Company Service Advantage: As a leading provider of cutting solutions, we are committed to customer satisfaction and excellent service. Our team of experts is dedicated to providing personalized assistance and guidance to help you select the right products for your specific drilling needs. We offer efficient and reliable shipping services to ensure timely delivery of your orders. Additionally, our comprehensive after-sales support aims to address any inquiries or concerns you may have, ensuring your satisfaction with our products. FAQ - Frequently Asked Questions: Q1:What machines are these core bits compatible with? Our core bits are compatible with machines ranging from 1.5-3.5Kw. For other specifications, please contact us for customization options.Q2:Can I customize the thread connection? Yes, we offer a variety of thread connections beyond the standard 1-1/4UNV. Customization is available upon request.Q3:How do I ensure the longevity of these core bits? Regular maintenance and proper use according to the specified power range and material type will help extend the life of your core bits.Q4:What makes these core bits ideal for reinforced concrete? The diamond segments are arranged in an ordered array, optimizing the bit for efficient and precise drilling in reinforced concrete.

Rubber Diamond Wires for Granite and Sandstone Mining Product Features: These Rubber Diamond Wires are the perfect solution for professional granite and sandstone extraction, offering high cutting precision, shock absorption, and extended service life. With customizable wire lengths and bead configurations, these wires ensure optimized performance in the toughest conditions, minimizing tool wear and operational downtime. Key Selling Points Durable and Flexible Design:Featuring a rubber coating that protects the diamond beads, the wire offers enhanced durability and flexibility, ensuring longer service life in harsh environments. High-Precision Cutting:The high-grade diamond beads ensure clean and accurate cuts, reducing material waste and enhancing productivity. Reduced Vibration:The flexible rubber structure absorbs cutting forces, providing smoother operation and less wear on equipment. Versatile Applications:Suitable for both wet and dry cutting, these wires can handle a variety of mining conditions and materials, including granite, sandstone, and composite materials. Customizable Solutions:Available in various wire lengths and bead configurations to suit different project requirements. Key Product Parameters: Technical Specification Details Wire Diameter 8.0mm, 9.0mm, 10.5mm,11.5mm (customizable) Beads Per Meter 28-32 beads per meter (standard options) Bead Diameter 10mm, 11mm, 12mm (customizable) Cutting Speed 15-35 m²/h (depending on material hardness) Cutting Type Wet and Dry Cutting Tensile Strength 2500N-3000N (ensuring stability during prolonged cutting) Service Life 20-25 m² per meter (depending on material and conditions) Cutting Applications Granite, Sandstone, Limestone, Composite Materials Cable Structure Rubber Coated, absorbs vibrations, enhances tensile strength Cutting Length Standard: 10m, 20m, 50m (custom lengths available) Applications: Granite Mining Sandstone Extraction Quarry Operations Architectural Stone Cutting Large-Scale Construction Projects Company Advantages: Extensive ExperienceOver 10 years in the diamond tool industry. Custom SolutionsTailored product specifications to meet diverse cutting needs. Strict Quality Control Rigorous testing ensures durability and cutting precision. Global Reach Efficient logistics and worldwide delivery. Technical Support Professional support and reliable after-sales service. Our dedicated customer service team is committed to providing prompt assistance and ensuring your complete satisfaction throughout the buying process. FAQ What materials can these diamond wires cut?Our Rubber Diamond Wires are designed for cutting granite, sandstone, and other natural stones. They are suitable for various stone extraction and mining operations. Are these wires suitable for both wet and dry cutting?Yes, the wires are designed for both wet and dry cutting, providing flexibility for different project needs. What is the lifespan of the wire?The lifespan of the diamond wires depends on the material being cut and operational conditions, typically ranging from 20-25 m² per meter of wire. Can the wire length be customized?Yes, we offer customizable wire lengths to suit specific project requirements. Please contact us for more details. What is the cutting speed of these diamond wires?The cutting speed ranges from 15-35 m²/h, depending on the hardness of the stone and operational factors.

Turbo Diamond Blade - Hot Pressed Wave Mesh Rim for Tile & Granite Product Description: Professional Diamond Wave Mesh Blade delivers 2x faster, zero-chipping cuts on tile and stone with 5x lifespan, engineered for precision and safety in DIY and professional renovations. Core Specifications · Material: Diamond-coated + High-strength alloy base (heat-resistant and anti-deformation) · Size: 105mm/125mm/180mm (compatible with angle grinders and tile saws) · Unique Design: 0.3mm ultra-thin diamond wave mesh (minimizes material waste) · Technology: Hot-press sintering (extends blade lifespan by 40%) · Versatility: Dry/wet cutting modes (ideal for dust-free or high-speed scenarios) Product specifications: - Cutting materials: ceramic tiles, ceramics, marble, granite DIAMETER SEGMENT BORE SIZE Inch mm T W N 4 105 1.3 10 1 20/22.23 Various holes upon request 4.5 115 1.3 10 1 5 125 1.4 10 1 6 150 1.6 10 1 7 180 1.8 10 1 8 200 1.8 10 1 9 230 2.0 10 1 10 250 2.0 10 1 12 300 2.2 10 1 Key Selling Points . 2x Faster Cutting SpeedWave mesh structure accelerates debris removal, enabling rapid tile and marble slicing without clogging. Perfect for time-sensitive projects. . Zero Chipping GuaranteeDiamond particles arranged in wave patterns distribute pressure evenly, delivering clean cuts on ceramics, glass, and granite. Eliminates post-cutting polishing. . 5x Longer LifespanReinforced alloy base with multi-layer diamond coating maintains sharpness after 2000+ meters of continuous use, outperforming standard resin blades. . Enhanced Safety Features Anti-splash coating and vibration-dampening holes reduce noise by 30% and prevent debris hazards, complying with EU safety standards. Choose our Diamond Blade For Cutting Tile to experience superior cutting efficiency, exceptional durability and exceptional precision. Transform your tile cutting projects with ease and confidence. Frequently Asked Questions (FAQ): - Q: Can this blade be used for dry cutting? A: Yes, our ultra-thin diamond web turbine blades are suitable for both wet and dry cutting applications. - Q: Is this blade compatible with marble and granite? Answer: Of course! It is designed to effectively cut ceramic, tile, marble and granite.

Silent Diamond Saw Blade for Granite, Marble, Quartz - Arix Segment Technology Product Description: AOYIN Silent Diamond Saw Blade features advanced Arix segment technology to ensure consistent diamond distribution for superior cutting efficiency and blade longevity. Designed for granite, marble, and quartz applications, this blade offers: Silent core structure for noise reduction Arix segment for fast, smooth, and clean cutting High durability with industrial-grade diamond concentration Ideal for bridge saws, edge cutting machines, and table saws Available diameters: 14" / 16" / 18"(350mm/400mm/450mm) Bore options: 50mm / 60mm (customizable) Segment height: 15mm / 20mm / 25mm (optional) OEM & ODM services available. Company Service Advantages: High-Quality Products: We are dedicated to providing high-quality products that meet industry standards. Our Diamond Silent Arix Saw Blade undergoes rigorous quality control measures to ensure superior performance and durability. Customer Support: Our customer support team is committed to providing prompt assistance and addressing any inquiries or concerns. We aim to offer exceptional customer service and ensure customer satisfaction. Wide Range of Products: In addition to the Diamond Silent Arix Saw Blade, we offer a diverse range of products to meet various needs in the stone industry. Explore our catalog for other cutting and polishing tools and accessories. FAQ - Frequently Asked Questions: Q: Can this saw blade be used for wet and dry cutting? A: Yes, the Diamond Silent Arix Saw Blade can be used for both wet and dry cutting. However, using water or a coolant during the cutting process can help to prolong the blade's lifespan and improve cutting efficiency. Q: What size options are available for this saw blade? A: The Diamond Silent Arix Saw Blade is available in various sizes to cater to different cutting requirements. Please refer to our product catalog or contact our customer support team for specific size options. Q: How long does the blade typically last under regular use? A: The lifespan of the Diamond Silent Arix Saw Blade will depend on various factors, including the intensity of use, material being cut, and the operator's technique. With proper care and maintenance, it can provide long-lasting performance and cost-effective cutting solutions. Note: Please follow safety precautions and use appropriate protective gear while operating the saw blade.

Hot Pressed Diamond Thin Turbo Blade for Granite Marble Dry Wet Use Product Description: The continuous Diamond Thin Turbo Blade is specifically designed for cutting granite and marble materials with precision and efficiency. The turbo segmented rim ensures smooth and fast cutting, while the thin blade design reduces material wastage during the cutting process. It is a versatile tool suitable for both wet and dry cutting applications. Product Specifications: Product Name Diamete (mm) Core Diameter (mm) Segment Dimension (mm) Segment Number Narrow Continuous Turbo Rim Blade 4Inch 105 20 22.23 25.4 T2.4*H10 56 - 110 T2.0*H10 64 4.5Inch 115 T2.4*H10 60 5Inch 125 T2.6*H10 64 5Inch 125 T2.6*H8 84 - 130 T2.6*H10 64 6Inch 150 T2.6*H10 75 7Inch 180 T2.8*H8 106 7Inch 180 T2.8*H10 96 8Inch 200 T2.8*H10 108 9Inch 230 T3.0*H10 120 Key Features: 1.Turbo Rim Design: Delivers smooth, chip-free cuts with precision-crafted edges for flawless finishes. 2.Constant-Contact Cutting: Maintains steady material interaction for cleaner results and 30% faster cutting speed. 3.Optimized Segment Geometry: Engineered depth/width ratios maximize material removal efficiency. FAQ: Q1: How to choose the right diamond tool for my project? A1: The choice of diamond tool depends on factors such as the material to be worked on, the desired finish, and the equipment being used. For example, for stone cutting, a continuous rim diamond blade is suitable, while a segmented diamond blade is more suitable for concrete. Q2: Can diamond tools be used on different types of stone? A2: Yes, diamond tools are versatile and can be used on various types of stones like granite, marble, limestone, and more. However, it is essential to ensure that the tool is specifically designed for the type of stone you intend to work on to achieve optimal results and avoid any damage. Q3: Are there any safety precautions to consider when using diamond tools? A3: Yes, when using diamond tools, it is crucial to follow safety guidelines. Wear protective gear such as safety glasses, ear protection, and gloves. Ensure that the work area is well-ventilated. Always read and follow the instructions provided by the tool manufacturer. Additionally, regularly inspect the tool for any damage and replace it if necessary. Q4: Do you offer customization or wholesale options for your products? A4: Yes, we offer customization services for specific tool requirements or bulk orders for our products. Please contact our customer service team with your specific needs, and we will be happy to assist you with customizing the tools or providing wholesale pricing information. For more detailed information and pricing, please contact our sales team. Please Note: - Always follow proper safety precautions and wear appropriate protective gear, including goggles, gloves, and a dust mask, when using the blade. - Cool the blade with water during wet cutting to prolong its lifespan and enhance cutting performance. - Avoid applying excessive pressure while cutting to prevent blade damage and ensure optimal cutting results.

Brazed Pagoda Reamer Drill Bit Hole Saw for Marble or Ceramic Product Description: Engineered for professional contractors, this diamond step drill bit undergoes aerospace-grade brazing to ensure diamond retention under extreme torque. Three precision-ground tiers allow progressive hole enlargement without tool changes. Product Parameters: Step Sizes: 20mm | 35mm | 50mm (±0.3mm tolerance) Max Depth: 40mm per step Shank: M14 thread (AR-14 adapter required for drills) Abrasive: 80/100 mesh synthetic diamond Compliance: CE/OSA certified Product Highlights: 1 Chip-Free Precision Drilling Achieves flawless holes in fragile marble/ceramics with vacuum-brazed diamond grits. 2 Pagoda Step Efficiency Triple-stage drilling (20/35/50mm) in one pass – eliminates tool changes. 3 Vein-Tracking Technology Automatically adapts to natural stone veins for zero-crack precision. Application Areas: Marble vanity sink cutouts Porcelain tile plumbing penetrations Granite countertop venting holes Company Service Advantage: We are committed to providing exceptional products and services to our customers. With our Electroplated Diamond Core Drill Bit, you can expect: 1. Premium Quality: We prioritize quality in every aspect of our manufacturing process. Our drill bits undergo rigorous testing to ensure superior performance and durability. 2. Customer Satisfaction: Customer satisfaction is our top priority. We strive to exceed your expectations by offering reliable products and excellent service before, during, and after your purchase. 3. Expert Support: Our team of experienced professionals is always ready to assist you with any questions or concerns you may have. We provide technical guidance and recommendations to help you make the most out of our products. FAQ - Frequently Asked Questions: Q1: Will this crack my marble slab during drilling? ► Zero-crack guarantee with vein-tracking technology – diamond grits automatically adjust pressure along natural stone veins. Always use water cooling for marble. Q2: Can it drill 50mm holes in one go? ► Pagoda Step Design lets you achieve 20/35/50mm sequentially in one pass. No bit changes needed. (Max. material thickness: 30mm) Q3: Will it work with my drill/driver? ► M14 thread fits angle grinders directly. Includes AD-14 adapter for standard drills (minimum 850W, 3000RPM). Q4: Dry or wet operation? ► Wet mode for stone (prevoves dust, extends life) | Dry mode for ceramic tiles (anti-grab flutes prevent snagging) Q6: Fix wobbling issues? ► Zero-wobble design: 1️⃣ Secure with M14 lock nut 2️⃣ Start drilling at 15° angle before vertical positioning

Brazed Pagoda Reamer Drill Bit Hole Saw for Marble or Ceramic Product Description: Professional vacuum-brazed diamond hole cutter engineered for chip-free drilling in stone countertops. Permanent diamond bonding eliminates segment shedding risks during marble/granite cutting, essential for sink/faucet installations in kitchens & bathrooms. Product Parameters: 45-60 mm、45-65mm、50-70mm、90-115mm Product Highlights: Featuring premium-grade diamond particles, it delivers exceptional cutting performance and durability. The vacuum brazing manufacturing technique further enhances product quality, while strategically placed side holes effectively dissipate heat to prolong tool life. For optimal results, operators should begin drilling at a 45-degree angle before gradually adjusting to 90 degrees - this technique maximizes efficiency and cutting precision. Application Areas: This diamond saw is specially designed for drilling holes in ceramic, porcelain, and tile materials. Marble vanity sink cutouts Porcelain tile plumbing penetrations Granite countertop venting holes Company Service Advantage: Our team of experienced professionals is always ready to assist you with any questions or concerns you may have. We provide technical guidance and recommendations to help you make the most out of our products. FAQ - Frequently Asked Questions: Q1: What materials is this saw designed for? A: This saw is specifically engineered for drilling clean holes in hard materials like ceramic, porcelain, and tile. Q2: What makes this saw durable and effective? A: Key features ensure performance and longevity: Premium Diamond Particles: Guarantee aggressive cutting power and high-quality results. Vacuum Brazing Technology: Creates an exceptionally strong bond between the diamonds and the core, enhancing overall durability and lifespan. Cooling Side Holes: Strategically placed to reduce friction heat buildup during drilling, preventing damage and extending the tool's life. Q3: What's the correct drilling technique? A: For best results and to prevent chipping: 1.Start at 45 Degrees: Begin drilling at a shallow angle to create a stable starting groove. 2. Adjust to 90 Degrees: Once the groove is established, gradually tilt the drill to a perpendicular (90-degree) position and continue drilling. This technique increases efficiency and hole quality. Q4: Why use vacuum brazing? A: Vacuum brazing is a high-quality manufacturing process that bonds the diamond particles directly and securely to the steel core. This results in: Stronger particle retention. Improved heat dissipation. Longer tool life compared to cheaper electroplated alternatives. Q5: How do the side holes help? A: The side holes serve two critical cooling functions: Heat Reduction: They allow air and/or coolant (if used) to flow, significantly reducing friction heat generated during drilling. Debris Removal: They help clear fine dust particles from the hole, improving cutting action and reducing wear.

Resin Filled Diamond Cup Wheel for Granite Marble Engineered Stone Product Overview: Our Resin-Filled Diamond Cup Wheels deliver chip-free grinding & honing by strategically placing diamonds for maximum speed while the specialized resin matrix eliminates bouncing/biting that causes material damage. Product Specifications: - Universal Compatibility: 5/8"-11 thread fits most angle grinders - Optimal Performance: 10,000 RPM recommended for maximum efficiency - Smart Color Coding: Instant grit identification at job site - Flexible Operation: Wet/Dry dual-mode (Wet recommended for dust suppression) Product Highlights: 40% faster material removal than standard wheels 85% less vibration for smoother operation Reduces follow-up polishing needs Applications: Our 4 Inch Diamond Resin Filled Cup Grinding Wheel is ideal for: - Grinding granite and marble surfaces - Shaping edges - Smoothing rough surfaces Company Service Advantage: We prioritize customer satisfaction and strive to provide excellent service at every stage.Our dedicated team is always ready to assist you with any inquiries, ensuring a seamless shopping experience.We offer prompt delivery, ensuring that your products reach you in a timely manner. FAQ (Frequently Asked Questions): 1. Q: Can I use this grinding wheel with a machine that has an M14 thread? A: Yes, our 4 Inch Diamond Resin Filled Cup Grinding Wheel is suitable for machines with an M14 thread. 2. Q: Is this grinding wheel compatible with machines that have a 5/8-11 thread? A: Absolutely, our grinding wheel is designed to fit machines with either an M14 or 5/8-11 thread. 3. Q: How long does the grinding wheel last? A: The durability of the grinding wheel depends on various factors such as the intensity of use and the hardness of the material being ground. However, our wheel is constructed to provide extended durability and long-lasting performance. Choose our 4 Inch Diamond Resin Filled Cup Grinding Wheel with M14 or 5/8-11 thread options for efficient grinding and precise results. Experience the convenience, durability, and efficiency it offers in your grinding projects.

Round Diamond Antique Brush for Stone Surface Treatment Product Overview: Professional diamond antique brushes for leathered/textured finishes on granite, quartz & porcelain, featuring 5/8"-11 thread & Snail Lock for angle grinders/Park Industries machines.Industrial-grade bristles with diamond-silicon formula deliver fast antiquing, anti-slip surfaces, and stain resistance, compatible with Frankfurt Fickert circular types (24#-1500#) Product Specifications: Applications: Compatible with angle grinders, arm/auto polishing machines, and floor polishers Creates anti-slip, stain-resistant surfaces while enhancing natural stone textures Ideal for achieving distressed/antique finishes on stone surfaces Available Types: Frankfurt/Fickert brushes (for uniform texture) Circular brushes (for edge detailing) Custom configurations upon request Advanced Abrasive Technology: Diamond-silicon hybrid formula for balanced cutting/polishing performance Multi-grit options: Coarse (24#-120#): Rapid material removal Medium (180#-500#): Texture refinement Fine (800#-1500#): Final surface conditioning Material Options: Steel-core brushes: Heavy-duty stone processing Rope-type brushes: Delicate surface texturing FAQ (Frequently Asked Questions): Q: What is the primary advantage of this brush? A: Engineered for high-speed antiquing on hard granite, quartzite, and quartz, it combines industrial-grade diamond filaments with reinforced construction to deliver maximum longevity and efficiency. Q: Which materials can it process? A: Creates a uniform leathered/textured finish on marble, granite, quartz, quartzite, and ultra-compact porcelain (sintered stone). Q: What defines a "leathered finish"? A: A tactile, matte surface with subtle texture that mimics leather, preserving stone veining while eliminating high-gloss reflection. Q: How does the dual arbor system enhance usability? A: Features integrated 5/8"-11 threaded and Snail Lock™ arbors for universal compatibility: 5/8"-11 thread: Fits Makita, Metabo, Flex, and Hercules hand grinders Snail Lock: Compatible with Park Industries Pro Edge, Wizard, Marmo edgers, and Fab King fabrication centers. Q: Why emphasize ultra-compact porcelain compatibility? A: Ultra-compact porcelain (Mohs 7+) exceeds natural stone hardness. Our reinforced diamond filaments resist wear while maintaining consistent texture output. Q: How is longevity improved vs. standard brushes? A: Diamond-impregnated filaments contain 40% higher abrasive density, tripling service life on hard stone with no loss of cutting aggressiveness. Q: How do I engage the Snail Lock arbor? A: Align brush pins with machine slots, then rotate the snail cam clockwise until audibly locked. Requires no tools (<10-second changeover). Q: Is water cooling required? A: Suitable for dry/wet use. Water cooling (≥1.5 L/min) is mandatory for granite/quartzite to prevent overheating and extend brush life. Company Service Advantage: we prioritize customer satisfaction and strive to provide excellent service at every stage. Our dedicated team is always ready to assist you with any inquiries, ensuring a seamless shopping experience. We offer prompt delivery, ensuring that your products reach you in a timely manner.

1-3/8" Dry/Wet T Shape Turbo Diamond Core Bit for Stone Product Description: Built for versatility, this 1-3/8" (35mm) core bit features a universal 5/8"-11 thread to fit most standard drills. Its dual dry/wet functionality works in any job site condition, while the T-segment steel body prevents breakage during handheld use—critical for safety and productivity. The combination of side diamonds and turbo segments ensures clean, even cuts with reduced chipping. Product Parameters: Thread Compatibility: Universal 5/8"-11 (fits most core drill motors) Max RPM: 6500 rotations per minute (optimal for balance between speed and bit life) Design: Turbo-style segments with side diamonds for efficient debris removal Material Compatibility: Granite, quartzite, marble, quartz, and other hard natural stones Usage: Wet or dry—no performance compromise Product Highlights: Breakage-Resistant Safety: The T-segment design embedded in the steel body minimizes flex and snapping during handheld operations—vital for job site security. Dual-Surface Cutting Power: Vacuum-brazed side diamonds + turbo segments deliver fast, consistent coring with minimal material waste. Efficient Debris Clearance: Turbo channels quickly evacuate dust and slurry, reducing cleanup time and improving drilling accuracy. Long-Lasting Durability: High-quality diamond segments and corrosion-resistant steel construction extend service life, lowering replacement costs. Versatile Application: Works for countertop holes, wall/ floor installations, and anchor placements in residential or commercial stone projects. Application Areas: Perfect for stone fabricators, construction crews, and tile installers needing to core holes in: Granite/quartz countertops Marble fireplace surrounds Stone flooring or wall cladding Outdoor stone fixtures (e.g., patios, fountains) Common uses: Running pipes/wires, installing anchors, or creating openings for hardware. Company Service Advantage: As a trusted provider of cutting solutions, we prioritize customer satisfaction and excellent service. Our team of experts is dedicated to providing personalized assistance and guidance to help you find the right tools for your specific drilling needs. We offer efficient and reliable shipping services to ensure timely delivery of your orders. Additionally, we provide comprehensive after-sales support, addressing any inquiries or concerns you may have, ensuring your satisfaction with our products. FAQ - Frequently Asked Questions: Q1: Can I use this bit dry? A: Yes—its dual dry/wet design supports both methods without sacrificing performance or bit life. Q2: What’s the maximum safe RPM? A: Rated for up to 6500 RPM—exceeding this may reduce durability. Q3: Will it fit my standard drill? A: Absolutely—its 5/8"-11 thread is universal for most core drill motors. Q4: What materials can it cut? A: Optimized for granite, quartzite, marble, quartz, and other hard natural stones. Q5: How does the T-segment prevent breakage? A: The T-shape is fused to the steel body, reducing vibration and flex during handheld use—critical for precision drilling.

Flexible Rubber Backing Pad for Polishing Pads - 5/8-11 & M14 Thread Product Description: These Rubber Backing Pads are the critical accessory for connecting diamond polishing pads to power tools. Crafted from high-quality rubber, they offer superior flexibility to contour stone edges, concave/convex surfaces, and curves—while the super-strength adhesive prevents pad delamination. A reinforced hook-and-loop Velcro keeps polishing pads securely attached, and an all-copper screw interface ensures stability even under heavy grinding pressure. Perfect for both angle grinders (portable jobs) and floor machines (large surface polishing). Product Specifications: Connection Type: 5/8”-11 Thread OR M14 Thread (compatible with 90%+ grinders/floor machines) Material: High-Density Rubber (resistant to tearing/warping) Backing Feature: Flexible + Excellent Rigidity (balances contouring and stability) Velcro System: Strong Adhesive Hook-and-Loop (peel strength: ≥12N/cm) Interface: All-Copper Screw (corrosion-resistant, prevents fall-off) Key Benefits: Long Lifespan | Quick Change | Stable Performance | No Separation Product Highlights: Unbreakable Durability: Premium aluminum alloy resists bending/warping—even after months of heavy use.No more replacing pads due to physical damage. Flawless Polishing Results: A perfectly flat surface ensures diamond pads lie flush,eliminating uneven scratches and achieving a high-gloss finish every time. No-More-Peeling Hook-and-Loop: Our Velcro stays attached through intense polishing sessions—saving you 10+ minutes/day on reattaching loose pads. Heat Defying Glue: Unlike cheap pads that delaminate when dry grinding, our glue resists melting—extending pad life by 30%. Lightweight & Comfortable: At just 150-200g (depending on size), it reduces hand fatigue during long workdays. Universal Fit: 3/4/5″ sizes + 5/8-11/M14 threads work with most electric/air grinders—no need for adapters. Applications: Marble Fabrication: Polishing kitchen countertops, floor tiles, or bathroom vanities for a mirror-like finish. Granite Countertops: Creating smooth edges and surfaces for residential/commercial kitchen installations. Engineered Stone: Polishing quartz or composite materials for custom furniture or cladding. Portable Grinding: Ideal for on-site jobs with handheld polishers or angle grinders. Company Service Advantage: At our company, we pride ourselves on providing exceptional customer service and support. Our experienced team is dedicated to assisting you throughout your purchasing journey, offering personalized advice, answering queries, and ensuring a smooth buying experience. We strive to exceed your expectations and deliver the highest quality products to meet your specific needs. FAQ - Frequently Asked Questions: Q1: Will this fit my grinder? A: It’s compatible with most electric/air grinders using 5/8-11″ or M14 threads—check your machine’s specs. Q2: Can I use wet and dry pads with it? A: Yes—our pad is designed for both wet and dry diamond pads. The aluminum material resists corrosion from water, too. Q3: How do I clean the hook-and-loop? A: Simply wipe with a dry cloth—avoid water or harsh chemicals, as they can weaken the adhesive over time. Q4: Why is this better than cheap aluminum pads? A: Cheap pads use low-grade aluminum (prone to bending) and weak glue (peels after 1-2 uses). Ours is premium materials for long-term reliability. Q5: What’s the weight difference vs. other pads? A: Our pad 20% lighter than most competitors—reducing hand strain during extended polishing.

Introduction Cutting a concrete block wall is a common task for renovations or installations, but it comes with risks—cracked blocks and misaligned door bucks can derail projects. The key lies in using the right approach, tools, and care. This guide breaks down the best method to cut cleanly,...

view moreToday, in the worlds of manufacturing and craftsmanship, if you are going to get great results, it is going to be imperative to work with very precise and efficient processes when you are carving that custom stone countertop, machining a metal prototype or creating some very detailed ceramic art. An...

For professionals tackling stone projects, choosing the right saw blade is critical for efficiency, precision, and safety. Diamond saw blades are universally recognized as the best solution for cutting stone—whether granite, marble, quartzite, or engineered materials like sintered stone slabs....

In the Ceramic Tile Processing Industry, diamond tools have become the standard equipment due to their exceptional wear resistance and efficient grinding capabilities. This comprehensive guide explores various types of diamond tools, their applications, and selection criteria to help you find the op...