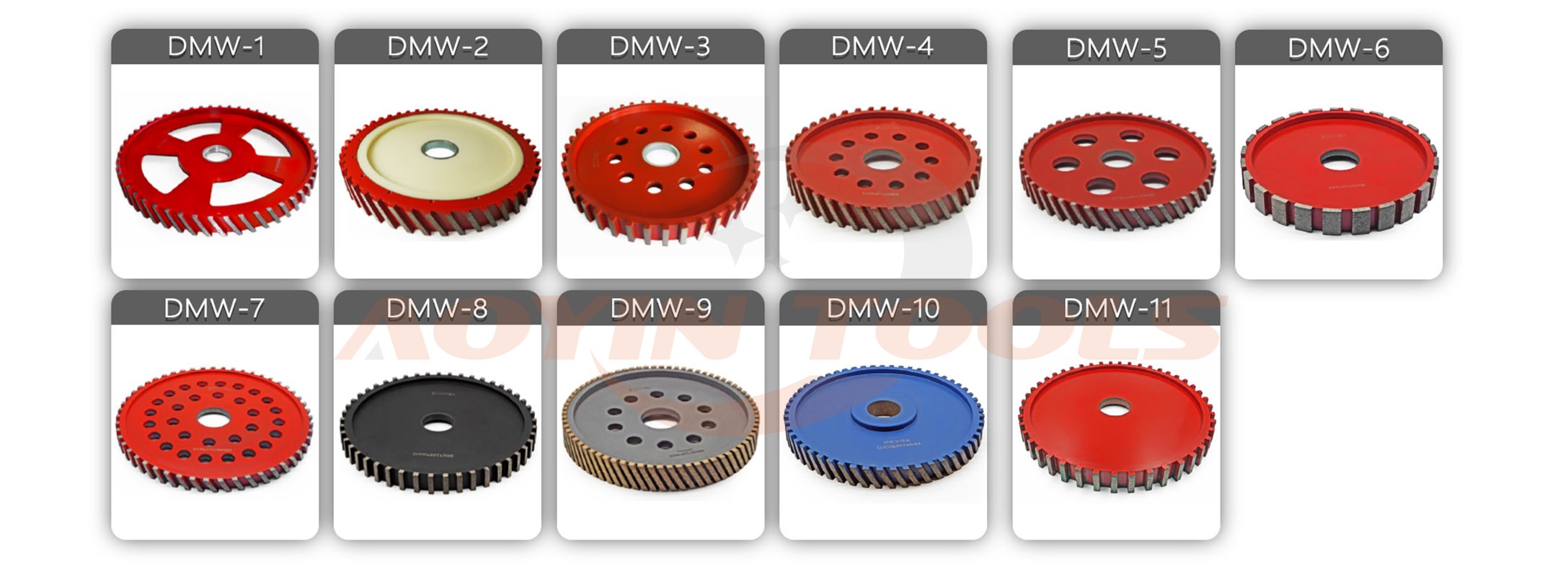

Our Diamond Milling Wheel with Big Holes is a precision calibration tool for stone surfaces, designed for edge cutting and bridge cutting machines—available in silent/non-silent versions with a lightweight nylon body for effortless handling and efficient operation.

Order(MOQ) :

5 pcsProduct Origin :

Fujian,ChinaColor :

RegularShipping Port :

Xiamen PortLead Time :

7-20 days after paymentCustomized support :

Visualization ServiceBrand Name :

OEMDiamond Milling Wheel with Big Holes for Stone Profiling & Calibrating

Product Description:

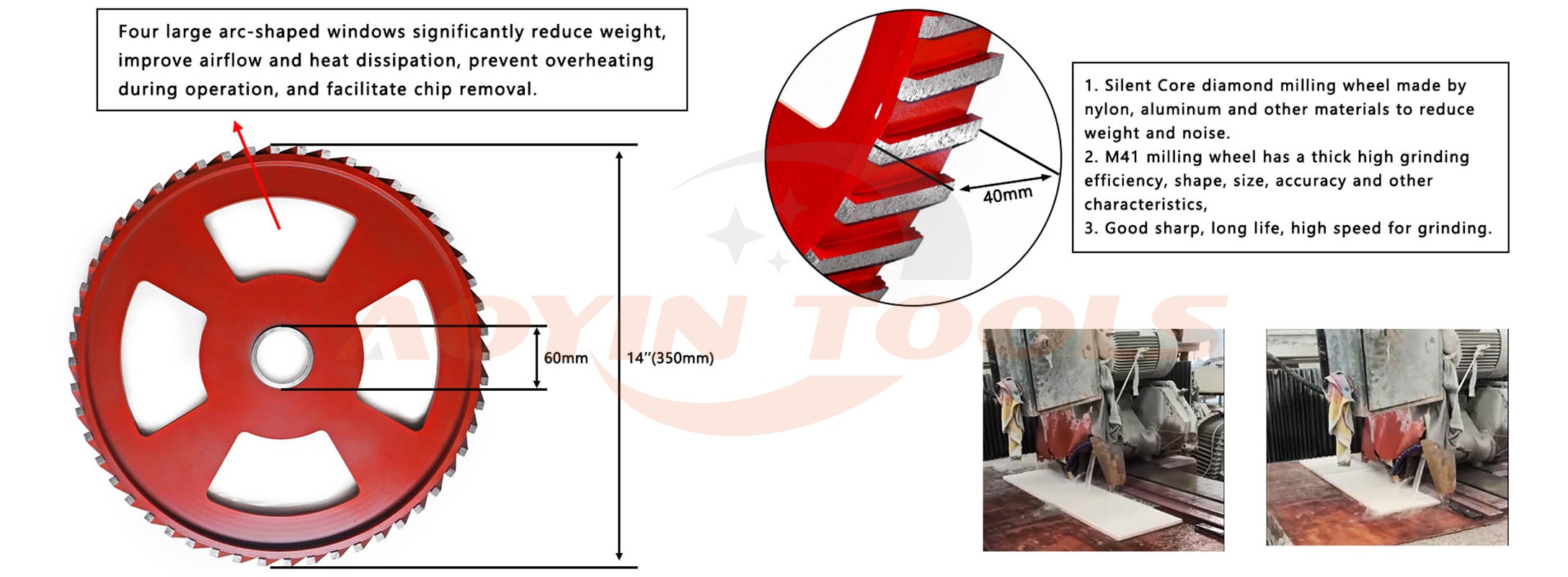

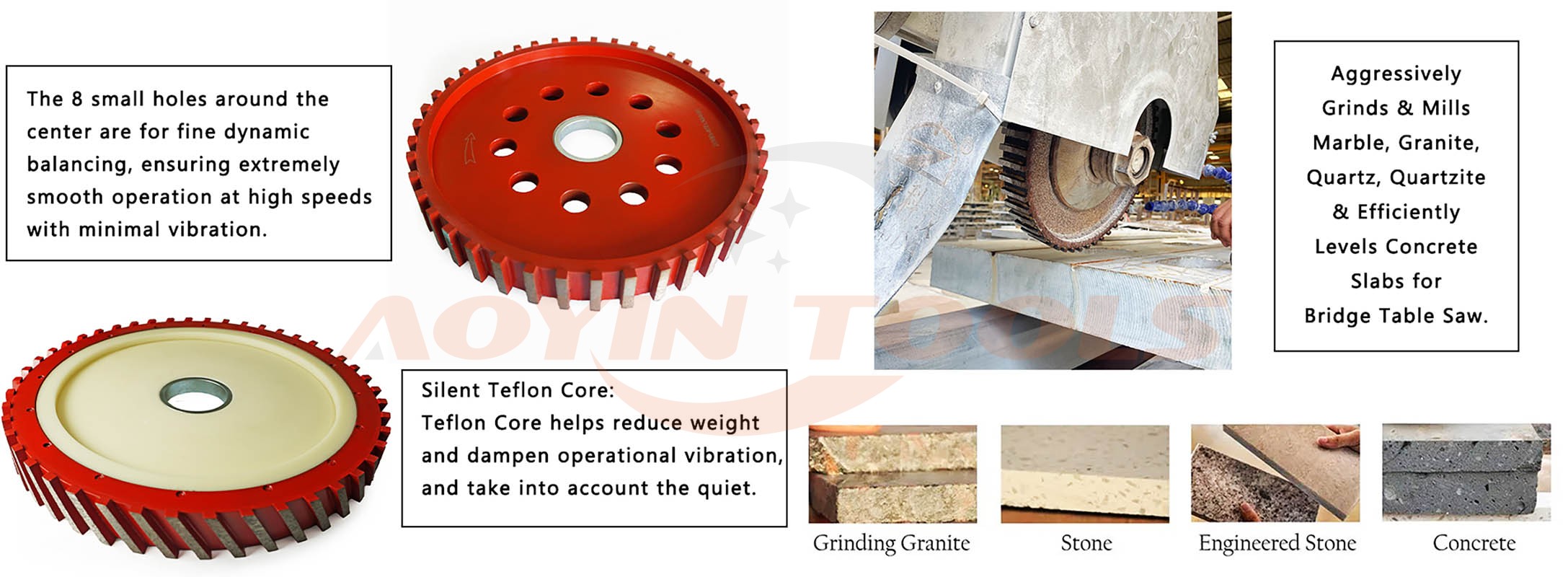

This Diamond Calibrating Wheel is engineered to deliver accurate calibration and leveling for stone slabs, concrete tables, and engineered stone surfaces. and is exclusively for wet useto optimize cutting performance and extend lifespan. The large central holes are strategically placed to minimize debris clogging and improve heat dissipation during extended use.

Product Parameters:

| Technical Specification | Details |

| Diameter | Ф150mm to Ф500mm |

| Thickness | 25mm,30mm,35mm,40mm,50mm |

| Material |

Nylon Body with Diamond Segments |

| Application |

Stone Surface Calibrating, Stone Edge Profiling |

| Compatible Machines |

Edge Cutting Machine, Bridge Cutting Machine |

| Noise Reduction |

Silent and non silent are available. |

Perfect for leveling uneven stone surfaces or prepping slabs for final polishing—ensures flatness and consistency.

Nylon body reduces vibration and fatigue, making it easy to maneuver on large cutting machines.

Large holes prevent clogging, reducing downtime and maintaining cutting speed.

Works seamlessly with both edge cutting and bridge cutting machines—ideal for multi-purpose workshops.

Choose silent versions for indoor or noise-sensitive environments (e.g., retail fabrication shops) or non-silent for heavy-duty industrial use.

Application Areas:

Widely used in stone processing facilities, marble/granite fabrication shops, and concrete product manufacturers—specifically for:

FAQ - Frequently Asked Questions:

Q1: Can this wheel be used on dry stone surfaces?

A: No—this milling wheel is designed exclusively for wet useto prevent overheating, reduce dust, and prolong the life of the diamond segments.

Q2: Which thickness should I pick for thin stone slabs?

A: For slabs under 20mm thick, we recommend the 25mm thickness option—it provides precise control without over-grinding.

Q3: How much quieter is the silent version?

A: The silent design reduces operational noise by ~30% compared to non-silent models, making it suitable for workshops with noise regulations.

Q4: Do you offer custom sizes?

A: We stock standard D300~D500mm diameters and 25-50mm thicknesses. Contact our team for custom requests (min. order applies).