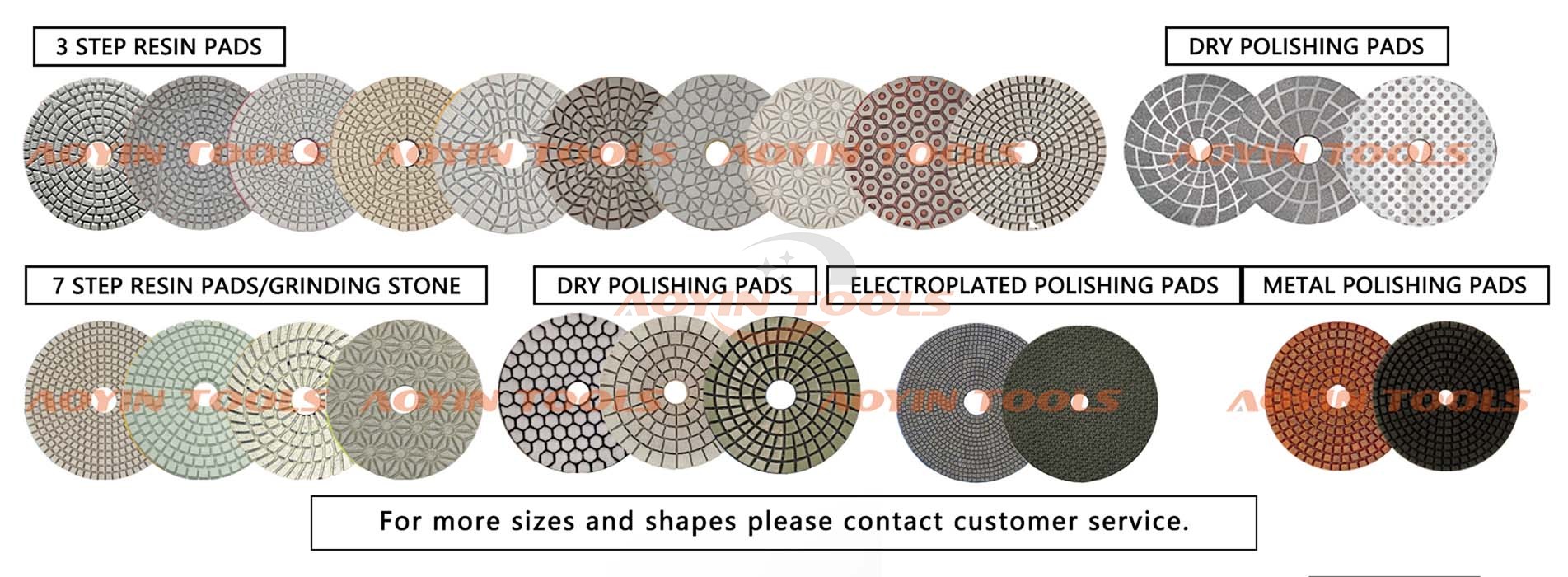

Diamond Dry Polishing Pads for Stone Grinder & Angle Grinder Granite/Marble/Concrete

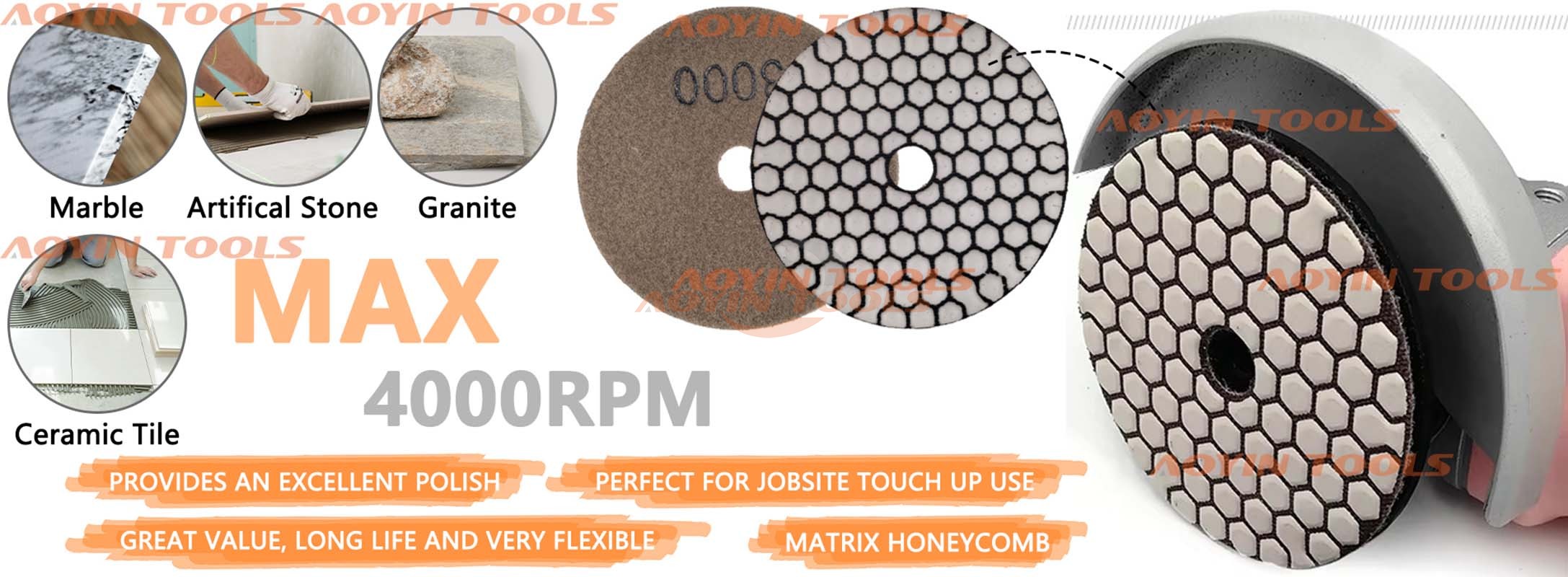

Our Honeycomb Matte finish Diamond Dry Polishing Pads deliver instant visual feedback during dry stone processing and demand minimal technical equipment—perfect for granite, marble, concrete, and technical stone projects where water access is limited. Ideal for on-site use without compromising finish quality.

Order(MOQ) :

30 pcsShipping Port :

Xiamen PortLead Time :

7~20 days after payment recievedCustomized support :

Visualization ServiceBrand Name :

OEMDiamond Dry Polishing Pads for Stone Grinder & Angle Grinder Granite/Marble/Concrete

Product Description:

Engineered for use with Stone Polishers and angle grinders (with regulation), these pads are built for dry polishing of granite, marble, concrete, ceramic, and technical stone. No water required—making them a go-to for construction sites, remote jobsites, or spaces where wet processing is impractical.

Product Specifications:

Available Diameters:80mm, 100mm, 125mm, 150mm, 180mm

Segment Height:2.0mm (balances durability and cutting efficiency)

Diamond Concentration:High (for consistent, long-lasting performance)

Binder Type:Optimized for granite, marble, and exposed concrete

Backing:Velcro (quick, secure attachment to grinders)

Grit Sequence:#30 (coarse) → #50/#100/#200 (grinding) → #400/#800 (color development) → #1500/#3000 (pre-mirror) → BUFF (mirror finish)

Product Highlights:

Instant Quality Checks: Dry polishing lets you visualize material progress immediately—no waiting for water to dry or post-process corrections.

Water-Free Flexibility: Use anywhere (construction sites, field work, indoor renovations) without relying on water supply.

All-in-One Finish: The full grit sequence eliminates the need for impregnation, color enhancers, or polishing paste—saving time and costs.

Size-Specific Performance:

80mm: Small manual grinders for tight corners, curves, or detailed stone carving.

100mm: Most popular size—best price/quality ratio for general stonework (arches, walls, floors).

125mm+/150mm+/180mm: Larger surface area for faster polishing of big projects.

Durable & Cost-Effective: High diamond concentration + optimized binder ensures long service life and consistent results—reducing replacement frequency.

Easy Setup: Velcro backing allows tool-free attachment to your polisher—getting you working faster.

Applications:

Construction Sites: Dry polish stone on-site without water constraints.

Stone Fabrication: Polish granite/marble arches, countertops, or flooring.

Stone Carving: 80mm pads for intricate details or hard-to-reach areas.

Repair & Refinishing: Restore shine to worn concrete, ceramic, or stone surfaces.

Company Service Advantage:

At our company, we pride ourselves on providing exceptional customer service and support.Our experienced team is dedicated to assisting you throughout your purchasing journey, offering personalized advice, answering queries, and ensuring a smooth buying experience. We strive to exceed your expectations and deliver the highest quality products to meet your specific needs.

FAQ - Frequently Asked Questions:

Q1: Why choose dry polishing pads over wet ones?

A: Dry pads skip water entirely—ideal for sites without water access (e.g., remote construction) and let you inspect results instantly.

Q2: Which diameter should I pick?

A: 80mm for small grinders/detail work; 100mm for most stonework (best value); 125mm+/150mm+/180mm for faster large-area polishing.

Q3: Do I need extra products after polishing?

A: No—our full grit sequence (#30 to BUFF) delivers a mirror finish without impregnation, color enhancers, or paste.

Q4: What makes these pads last longer?

A: High diamond concentration + a binder formulated for granite, marble, and concrete resists wear and maintains performance.

Q5: Are they easy to attach?

A: Yes—Velcro backing makes installation quick and secure—no tools required.