Our B20 350mm Sintered Profiling Wheel delivers precision edge profiling for granite, engineered stone, and natural stones—compatible with edge cutting and bridge cutting machines, ideal for high-volume stone fabrication businesses seeking durable, consistent results.

Order(MOQ) :

5 pcsProduct Origin :

Fujian,ChinaColor :

RegularShipping Port :

Xiamen PortLead Time :

7-20 days after paymentCustomized support :

Visualization ServiceBrand Name :

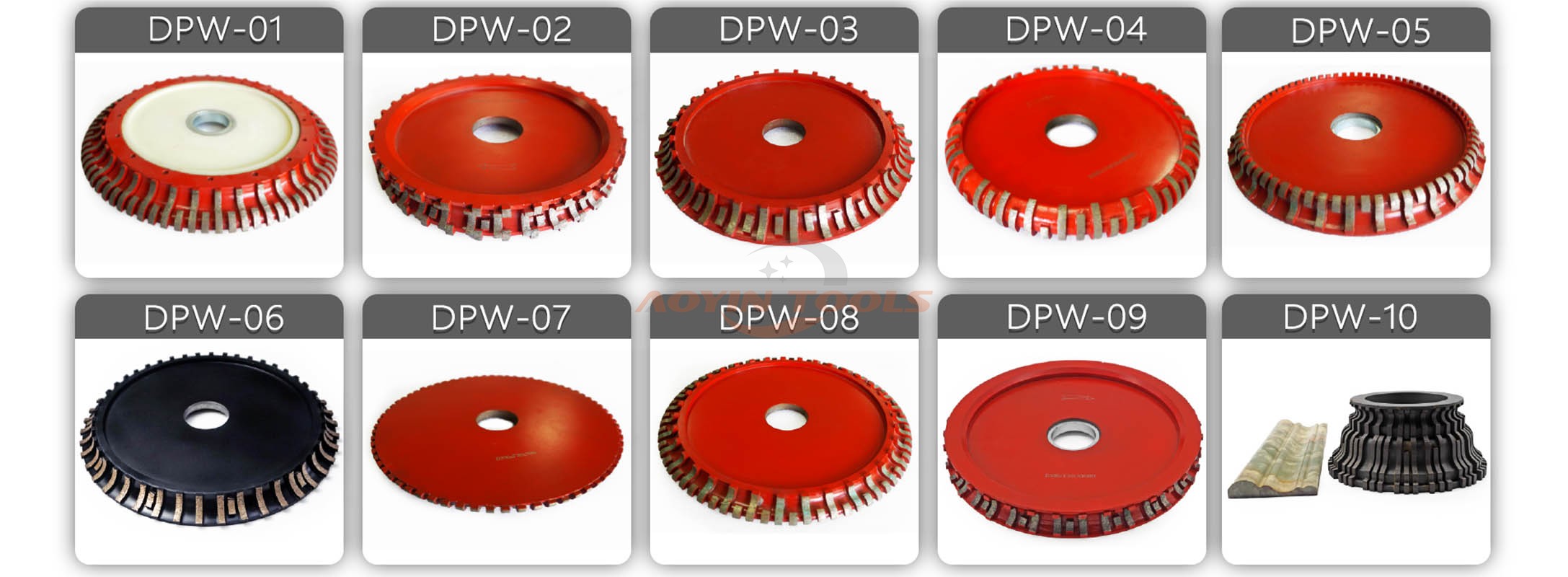

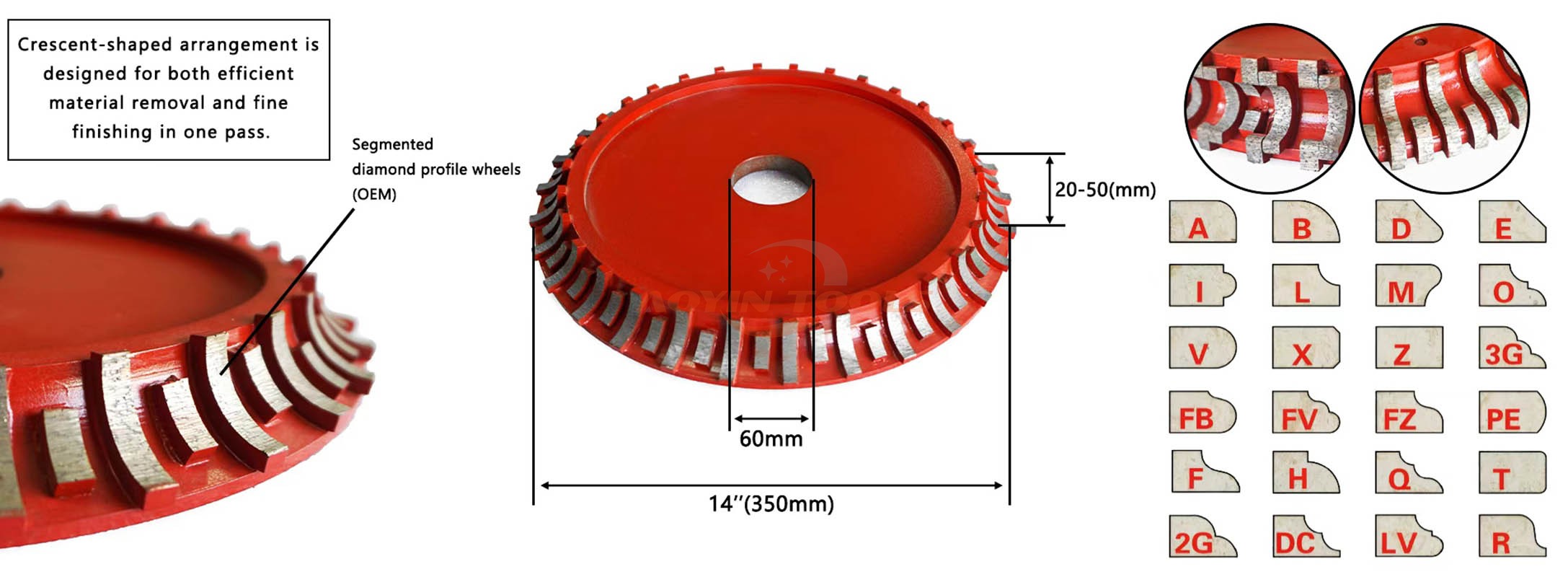

OEMB20 350mm Sintered Diamond Profiling Wheel for Granite & Stone Fabrication

Product Description:

This Segmented Diamond Profiling Wheel is engineered to create smooth, accurate edges on granite, engineered stone, and natural stone surfaces. Its robust sintered diamond construction and bullnose shape combine for long-lasting performance and efficient debris removal, making it a go-to tool for stone fabrication shops.

Product Parameters:

Perfect for:

Stone fabrication shops creating granite countertops or engineered stone slabs.

Countertop manufacturers needing precise edge profiling for residential/commercial projects.

Architectural stone processors working with natural stone tiles or cladding.

FAQ - Frequently Asked Questions:

Q1: Can this wheel be used on engineered stone?

A: Yes—its sintered diamond formula is optimized for engineered stone, granite, and natural stone, delivering chip-free, smooth edges.

Q2: Will it fit my bridge cutting machine?

A: The Φ50/φ60 thread is compatible with most standard machines. Please confirm your machine’s specs before ordering, and we’ll double-check for you.

Q3: Do you offer custom sizes?

A: Absolutely—we can adjust diameter, segment count, or shape to meet your specific fabrication needs (e.g., tighter radii for decorative edges).

Q4: How long does this wheel last compared to others?

A: Our sintered construction extends lifespan by 30-50% vs. non-sintered wheels in high-volume use—backed by customer feedback from fabrication shops.