Engineered for precision wet grinding of polished, glazed, and low-absorption ceramic tiles, our Metal Bonded Diamond Discs deliver 0.2% edge crack control - a critical metric for tile manufacturers prioritizing yield rates. With 15,000-28,000㎡ daily output, this solution directly boosts your production efficiency.

Order(MOQ) :

20 pcsColor :

RegularShipping Port :

Xiamen PortLead Time :

7-20 days after paymentCustomized support :

Visualization ServiceBrand Name :

OEMWet Metal Bonded Diamond Rear Grinding Wheel For Ceramic Tile

Product Description:

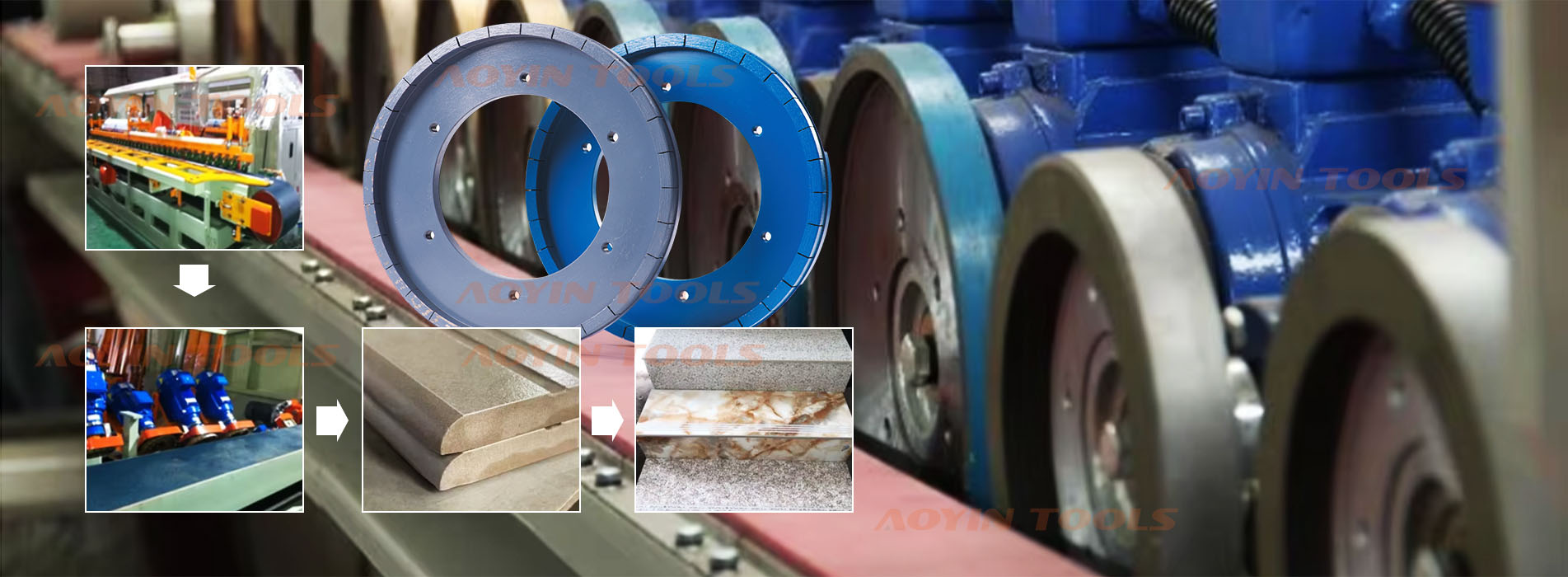

Industrial-grade Metal Bonded Diamond Grinding Wheel specially designed for rear grinding/back grinding of:

Polished tiles

Polishing glazed tiles

Diamond glazed tiles

Other low water absorption ceramic tiles

Product Parameters:

Representative specifcations: 250(200)×26×140(80)×9×14mm

Metal Bond Matrix: Fe-Co-Ni alloy for extreme durability

Compatibility: Breton/Simec/CNC tile processing lines

Product Highlights:

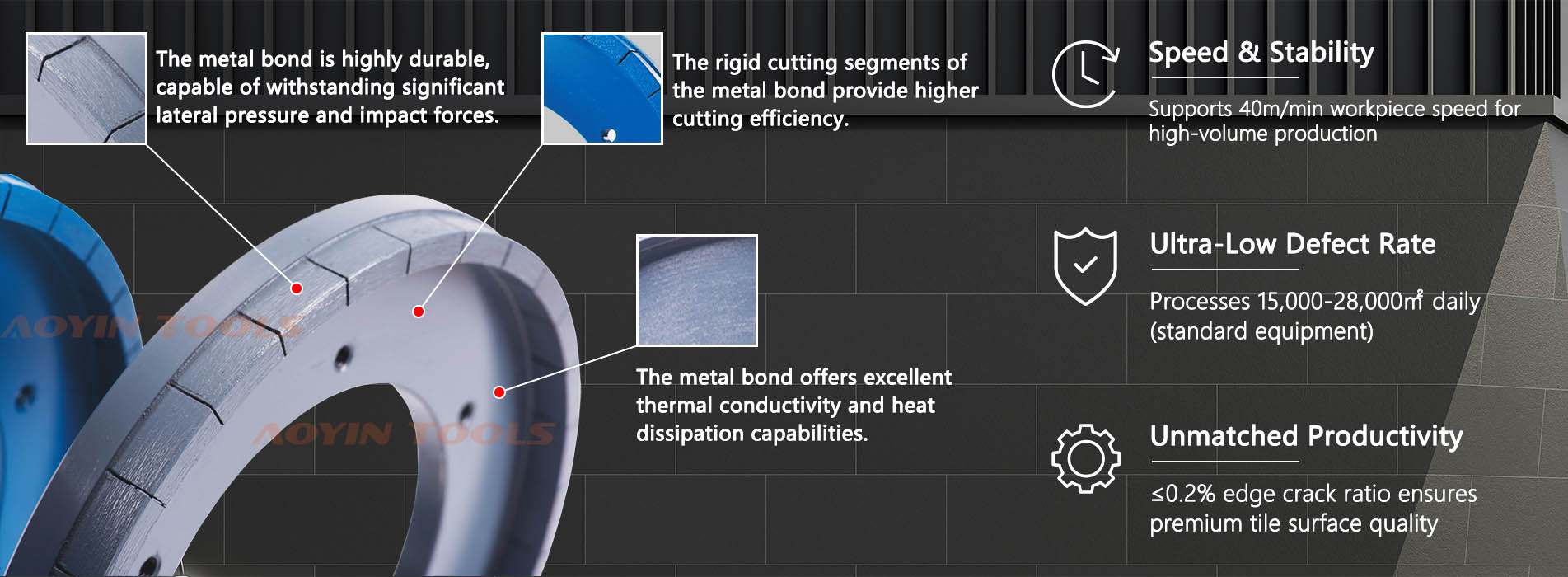

1.Ultra-Low Defect Rate

2.Unmatched Productivity

3.Speed & Stability

Company Service Advantages:

We are committed to providing high-quality products that meet industry standards.

Q: Metal vs resin bond for tile grinding?

A: Metal bond excels in wet grinding with 3x longer life and better heat dissipation.

Q: Recommended coolant flow rate?

A: 8-12L/min for optimal chip removal.

Q: How to identify wear?

A: Monitor current load - >15% increase indicates dressing needed.

Q: How to determine when the grinding wheel needs replacement?

A: Replacement is required when the following occur:

① Daily output decreases by >15% (compared to the baseline 13,000 sqm)

② Tile edge chipping rate exceeds 0.3%

③ Grinding noise exceeds 85 dB