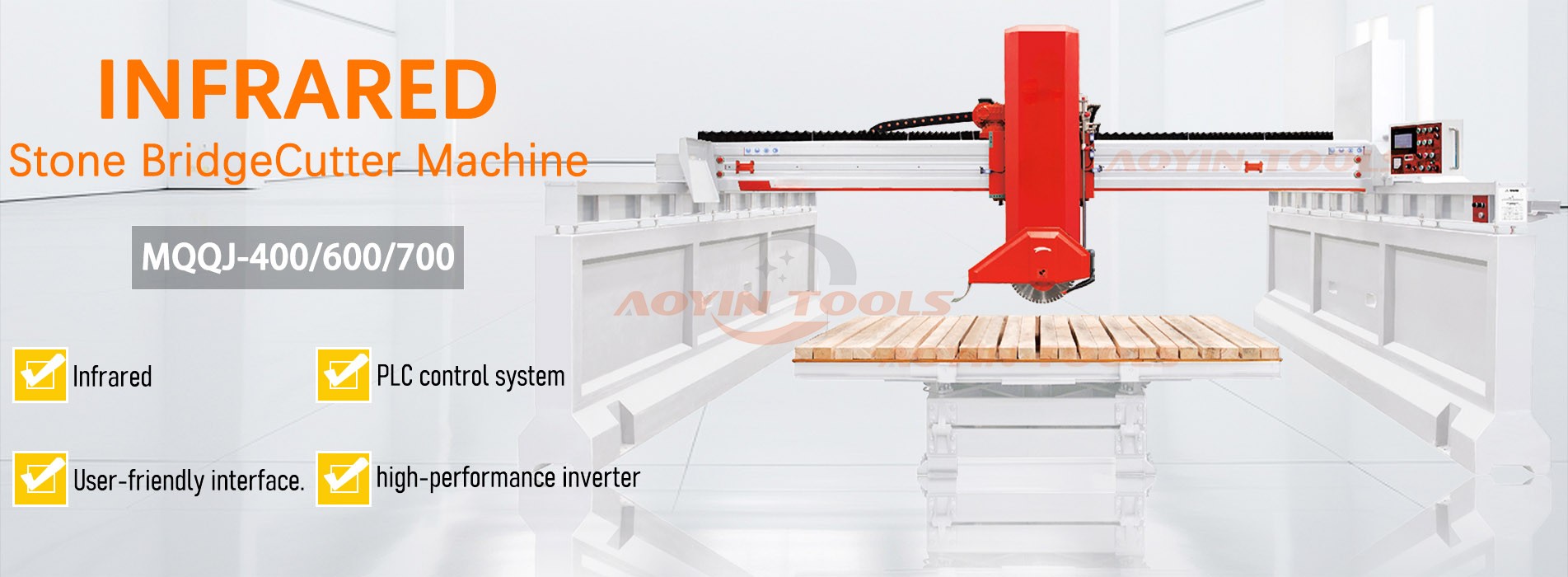

MQQJ-400/600/700 Infrared Bridge Cutting Machine, a cutting-edge solution designed for efficient and precise slab processing. This innovative machine combines advanced technologies such as programmer logic controller, precision frequency converter and signature laser to provide automated functions and ensure a stable cutting process.

Color :

CustomizedShipping Port :

Xiamen PortLead Time :

7-35 days after paymentCustomized support :

Visualization ServiceBrand Name :

OEMCompetitive Price Laser Stone Bridge Cutting Machine

The core of the MQQJ-400/600/700 Infrared Stone Bridge Cutting Machine lies in its intelligent control system, namely the Programming Logic Controller (PLC).This advanced control system not only enables the machine to operate automatically, but also ensures the accuracy and stability of the cutting process.With the help of PLC, operators can effortlessly perform complex cutting tasks with the highest precision.

| (Model) | Unit | MQQJ-400 | MQQJ-600 | MQQJ-700 |

| Max. Diameter of Blade | mm | Φ400 | Φ600 | Φ700 |

| Main Motor Power | kw | 15 | 18.5 | 22 |

| Total Power | kw | 21 | 24 | 28 |

| Worktable Dimensions (LxW) | mm | 3200x2000 | ||

| Worktable Turn-over Degree | ° | 0~85° | ||

| Worktable Rotation Degree(optional) | ° | 0~90°(0~360°/ (Setup by each 45°)optional) | ||

| Max. Cutting Size(LxWxH) | mm | 3200x2000x100 | 3200x2000x180 | 3200x2000x230 |

| Water Consumption | m³/h | 3 | ||

| Dimensions(LxWxH) | mm | 6000x4800x3100 | 6000x4800x3300 | 6000x4800x3400 |

| weight | kg | 5600 | 5800 | 6000 |

Features

Another outstanding feature of this cutting machine is its fine frequency converter.This innovative technology enables the machine to adjust cutting speed to meet the specific requirements of different stone materials, resulting in efficient cutting without compromising quality.The ability to optimize cutting speed based on the material being processed is a game changer for the stone cutting industry, increasing productivity and reducing material waste.

In addition, the MQQJ-400/600/700 is equipped with a high-precision signature laser.The laser helps operators accurately align cutting lines, ensuring the highest precision in every cut.This advanced laser technology eliminates the need for manual measurements, reducing human error and saving valuable time.

Product Details

The MQQJ-400/600/700 infrared bridge cutting machine comes with impressive specifications, making it ideal for a variety of applications.Its maximum cutting stroke can reach 3200mm, providing sufficient space for processing large slabs. Cutting thickness ranges from 10mm to 220mm to meet various project requirements.

Ideal for applications such as kitchen countertops, vanity tops and decorative panels, this cutter can process materials such as granite, marble, quartz and other stone types.Its sturdy construction ensures durability and longevity, even under demanding working conditions.

In addition to excellent cutting performance, the MQQJ-400/600/700 also offers excellent service advantages.With its advanced automation features, operators can reduce labor costs and increase productivity. The machine’s precise cutting capabilities reduce material waste, further saving users money.

FAQ:

1. Is MQQJ-400/600/700 suitable for small and large stone processing projects?

Yes, the machine’s flexible design and adjustable settings make it suitable for projects of all sizes.

2. Does the infrared bridge cutting machine require a lot of maintenance?

No, this cutter is designed for low maintenance requirements, ensuring operators can focus on their tasks with minimal downtime.

3. Can MQQJ-400/600/700 cut all types of stone?

Yes, this machine is capable of processing a variety of stone materials, including granite, marble, quartz, and more.